This post is a continuation of the Interactive Blocks projects posted here: http://hapticaction.blogspot.com/2014/03/andre-assignment-8-interactive-blocks.html

In my previous post, I expressed interest in using LEDs as sensors using a phenomenon called parasitic capacitance. Given that I did not have two sets of micro-controllers lying around to interact with each other, I explored other things that I had sitting around.

I've always been interested in working with camera flashes. The sound while charging that it makes is both terrifying and provides an anticipatory signal to people letting them know that its getting ready for a bang.

Typically, these flashes are trigged manually with physical switches, but I wanted to see if I could get an Arduino to trigger it using other sensors.

The Hack:

The first step was to extract the flash unit from the disposable camera. Looking around the edges, I was able to find a few clips that allowed me to detach the front and back housings. Visually, you can see where the contacts are to charge the capacitor and where it's triggered.

Next, I had to test my assumptions of how it worked with a piece of metal. I charged and discharged the flash in the video above. After I confirmed that it worked, I went to prototype a circuit that contained a relay, transistor to trigger the relay, and a photoresistor as the sensor.

I had to keep in mind that I needed to provide a minimal amount of connections across the two blocks. I managed to share a lot of connections on the circuit board and only expose pins for power, ground, relay signal, and sensor signal.

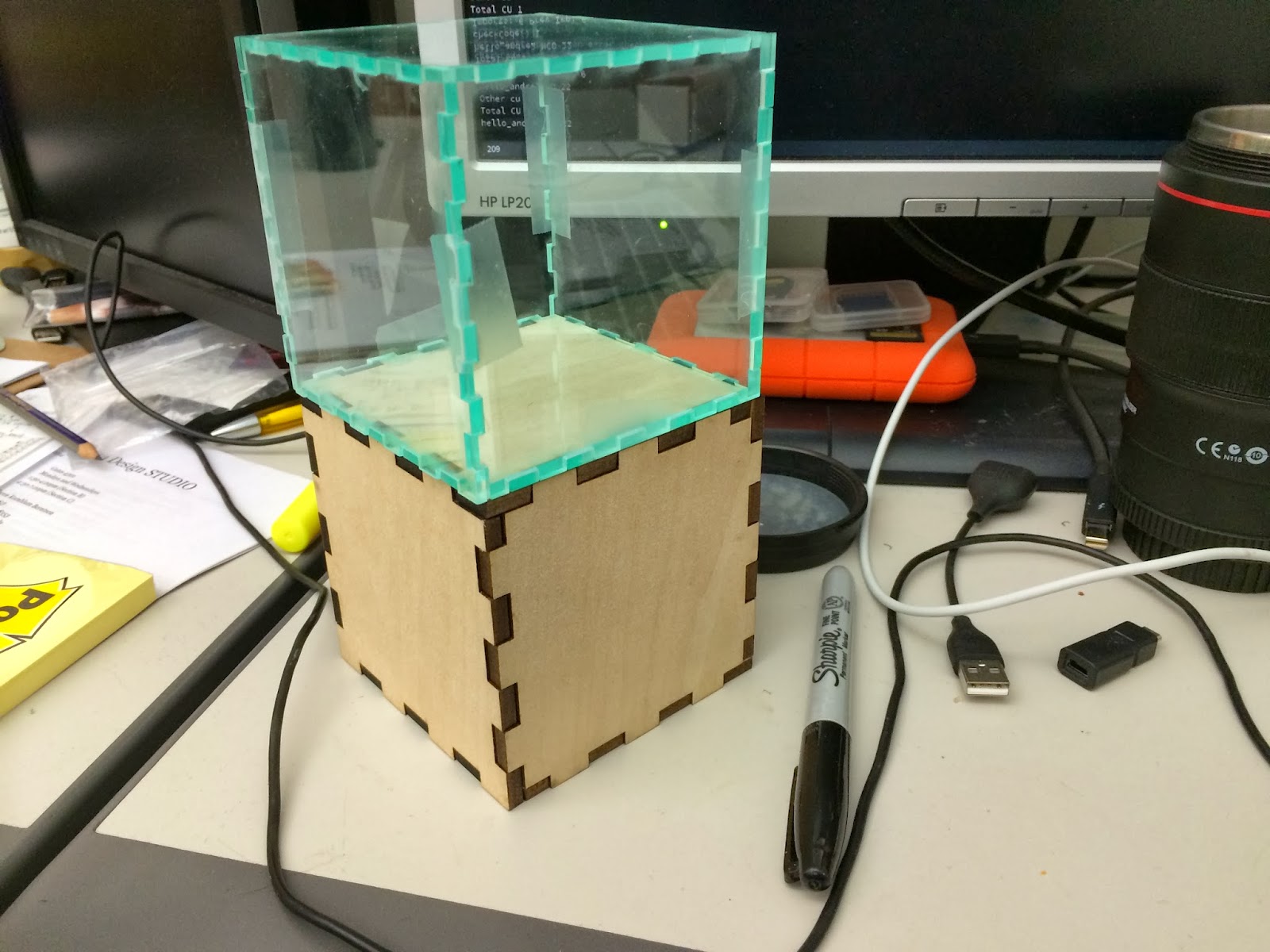

This allowed me to use screws to double up as both standoffs and connections to the Arduino in the wooden box.

To make connections on the wooden side of the box, I needed a way to insert the screws into the box and make a solid connection. The conductive material would need to be fluffy enough to fill the holes, but give way to the screws as they were seated together. I tested some steel wool used for dishwashing with my multimeter and realized that the resistance was very low. I took several bundles of steel wool and soldered jumper wires to them to make the final connections to the Arduino. This solution worked well for my tests and is a novel way to connect two objects, but I would definitely need some safeguards to prevent shorting in a production environment.

The screws were also keyed, arranged in a pattern that would not allow you to put them in the wrong way.

Independently, the cubes do not do anything. But once you mate the two cubes together, the unit acts as a display case for the circuit board. The wooden box hides an Arduino and battery, which provides the clear box with the computational power to determine when and how the flash is activated. The Arduino initializes by taking a light reading of the environment. If the light changes drastically, the Arduino is "spooked" and discharges the flash.